Crushers and mills are essential equipment in material size reduction processes for mining, construction, chemical processing, and manufacturing. They break down materials into smaller sizes for further processing or utilization. This guide covers various types of crushers and mills conforming to ISO 10628-2 standards.

Crushers and mills are represented in P&IDs with specific symbols indicating their operational principles and configurations:

| Symbol | Name | Description |

|---|---|---|

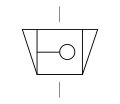

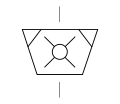

| Crusher | General-purpose crusher for material size reduction. |

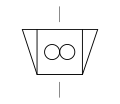

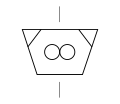

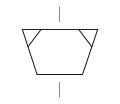

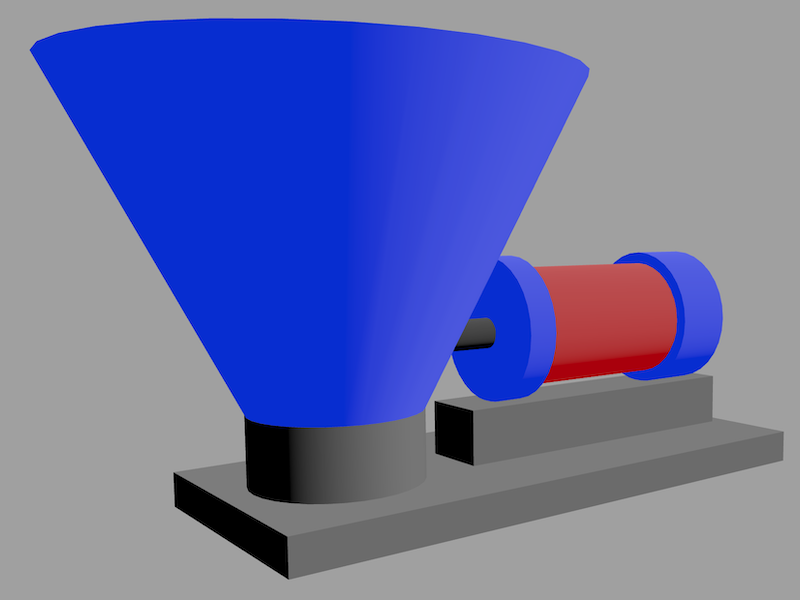

| Crusher Cone Type | Features a conical crushing chamber for fine material reduction. |

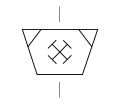

| Crusher Hammer Type | Features a conical crushing chamber for fine material reduction. |

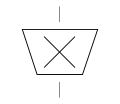

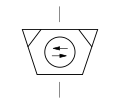

| Crusher Impact Type | Operates by applying high-speed impact force. |

| Crusher Jaw Type | Utilizes compressive force with a fixed and moving jaw. |

| Crusher Roller Type | Uses rollers to crush and grind materials. |

| Grinder | General-purpose grinding device for material pulverization. |

| Mill Horizontal Rotation Roller Type | Employs rotating rollers for grinding materials. |

| Mill Impact Type | Uses impact forces to break down materials. |

| Mill Pulverizer | General-purpose pulverizer for reducing materials to fine powders. |

| Mill Pulverizer Hammer Type | Utilizes hammering action to pulverize materials. |

| Mill Vibration Type | Uses vibration to pulverize and mix materials. |

Crushers and mills are used in applications requiring material size reduction, including:

Crusher (General)

Crusher Cone Type

Crusher Hammer Type

Crusher Impact Type

Crusher Jaw Type

Crusher Roller Type

Grinder

Mill Horizontal Rotation Roller Type

Mill Impact Type

Mill Pulverizer

Mill Pulverizer Hammer Type

Mill Vibration Type

| Attribute | Details |

|---|---|

| Equipment Type | Crusher, Mill |

| Design | Jaw, Cone, Hammer, Impact, Roller |

| Operation | Crushing, Grinding, Pulverizing |

| Standards | ISO 10628-2, ASME |

| Industries | Mining, Construction, Chemicals |

| Component | Material Options |

|---|---|

| Casing | Cast Iron, Carbon Steel, Stainless Steel |

| Blades/Rollers | Hardened Steel, Alloy Steel |

| Seals | PTFE, Graphite |

| Bearings | High-Speed, Ceramic |

| Attribute | Options |

|---|---|

| Capacity Range | 10 kg/h to 10,000 kg/h |

| Output Size | 0.1 mm to 100 mm |

| Speed Range | 500 to 10,000 RPM |

| Power Rating | 5 kW to 500 kW |

| Accessory | Details |

|---|---|

| Vibration Monitoring System | Ensures operational safety |

| Control Panel | Automates operation and monitoring |

| Dust Collectors | Minimizes environmental impact |

| Cooling System | Prevents overheating during operation |

| Attribute | Value |

|---|---|

| Material | Cast Iron |

| Type | Jaw Crusher |

| Capacity | 500 kg/h |

| Output Size | 10 mm |

| Application | Mining |

Explore micro data sheets for crushers and mills using mD.

Explore vendors for crushers and mills in your region using Mails AI.

| Parameter | Specification | Estimated Cost |

|---|---|---|

| Material | Hardened Steel | $10,000 - $100,000 |

| Type | Cone Crusher | $50,000 - $300,000 |

| Capacity | 1,000 kg/h | $30,000 - $200,000 |

For accurate pricing of crushers and mills, access cost data using Cost AI.

To integrate this 3D model of a crusher in a Process Plant use Model Builder. Download crusher.json. Choose File > Import and use the downloaded file to add the model to the scene. Choose Add > Light > Directional to add directional light.

Crushers and mills are indispensable for material size reduction in industrial processes. Their diverse designs and operational capabilities make them adaptable for a wide range of applications. Use this guide alongside tools like mD (Micro Data Sheets), Vendor Lists, and Cost AI to make informed decisions and optimize your processes.