Centrifuges are mechanical devices designed to separate components of a mixture based on their density by applying a centrifugal force. Widely used in industries such as pharmaceuticals, chemical processing, food and beverage, and wastewater treatment, centrifuges are essential for efficient solid-liquid or liquid-liquid separation. This guide provides a comprehensive overview of various types of centrifuges, conforming to ISO 10628-2 standards.

Centrifuges are represented in P&IDs with distinct symbols highlighting their operational principles:

| Symbol | Name | Description |

|---|---|---|

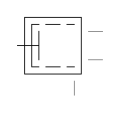

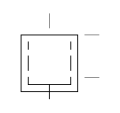

| Centrifuge Pusher Type | A device for density-based separation using with a reciprocating pusher mechanism. |

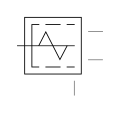

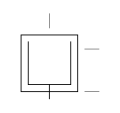

| Centrifuge Screw Type with Perforated Shell | A device for density-based separation with a perforated shell for dewatering applications. |

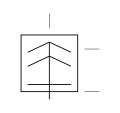

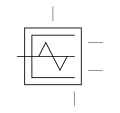

| Centrifuge Separator Disc Type | A device that employs disc stacks for high-speed separation of liquid-liquid and liquid-solid mixtures. |

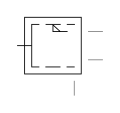

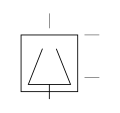

| Centrifuge Skimmer Type | A device that is designed for efficient skimming of light fractions from liquids. |

| Centrifuge with Perforated Shell | A device that features a perforated drum for separating solids from liquids in batch operations. |

| Centrifuge with Solid Shell | A device that utilizes a solid shell for handling dense slurries and viscous materials. |

| Decanter Centrifuge Screw Type with Solid Shell | A device that combines a screw conveyor and a solid shell for continuous separation of high-solid-content mixtures. |

| High-Speed Centrifuge | A device that operates at extremely high rotational speeds for precise separation of fine particles. |

Centrifuges are used in a variety of applications requiring efficient separation processes, including:

| Attribute | Details |

|---|---|

| Equipment Type | Centrifuge |

| Design | Pusher, Screw, Disc, Skimmer, Solid Shell, Perforated Shell |

| Operation | Continuous, Batch |

| Standards | ISO 10628-2, ASME |

| Industries | Pharmaceuticals, Chemicals, Food and Beverage |

| Component | Material Options |

|---|---|

| Shell | Stainless Steel, Carbon Steel |

| Rotor | Stainless Steel, Alloy Steel |

| Seals | PTFE, Viton |

| Bearings | High-Speed, Ceramic |

| Attribute | Options |

|---|---|

| Size Range | 1 liter to 10,000 liters |

| Speed Range | 500 to 30,000 RPM |

| Temperature Range | -20°C to 200°C |

| Pressure Rating | Up to 10 bar |

| Accessory | Details |

|---|---|

| Control Panel | For automated operation |

| Discharge Chutes | Simplifies solid removal |

| Vibration Monitoring System | Ensures operational safety |

| Attribute | Value |

|---|---|

| Material | Stainless Steel |

| Type | Separator Disc Type |

| Capacity | 500 liters |

| Speed | 12,000 RPM |

| Application | Food and Beverage |

Explore micro data sheets for centrifuges using mD.

Explore vendors for centrifuges in your region using Mails AI.

| Parameter | Specification | Estimated Cost |

|---|---|---|

| Material | Stainless Steel | $20,000 - $100,000 |

| Type | Separator Disc | $30,000 - $150,000 |

| Capacity | 500 liters | $50,000 - $200,000 |

For accurate pricing of centrifuges, access cost data using Cost AI.

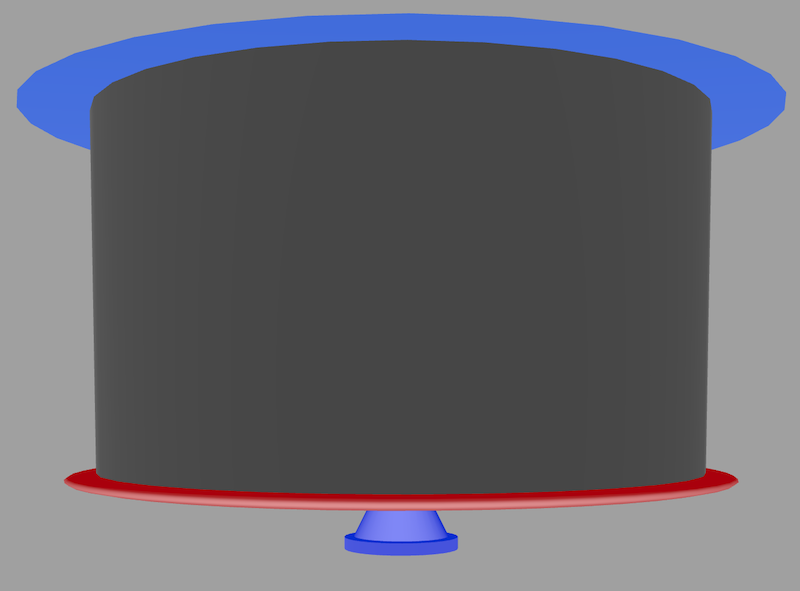

To integrate this 3D model of an centrifuges in a Process Plant use Model Builder. Download centrifuge.json. Choose File > Import and use the downloaded file to add the model to the scene. Choose Add > Light > Directional to add directional light.

Centrifuges are vital for separation processes in a wide range of industries. Their diverse designs and operational capabilities make them adaptable for various applications. Use this guide alongside tools like mD (Micro Data Sheets), Vendor Lists, and Cost AI to make informed decisions and optimize your processes.