Compressors are essential mechanical devices designed to increase the pressure of gases or create a vacuum by reducing their volume. Widely used in industries such as oil and gas, petrochemicals, food and beverage, and pharmaceuticals, compressors play a crucial role in enabling processes like refrigeration, gas transfer, and vacuum creation. This guide covers various types of compressors conforming to ISO 10628-2 standards.

Compressors are represented in P&IDs with distinct symbols that highlight their operational principles and configurations:

| Symbol | Name | Description |

|---|---|---|

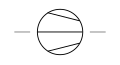

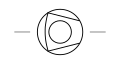

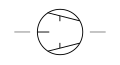

| Compressor Centrifugal Type | A mechanical device that uses a high-speed impeller to compress gases. |

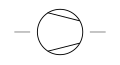

| Compressor Ejector Type (Vacuum Pump Jet) | A mechanical device that operates by creating a vacuum using high-velocity jet streams. |

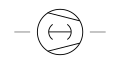

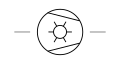

| Compressor Rotary Type (Vacuum Pump Rotary Piston Type) | A mechanical device that utilizes a rotating piston mechanism to compress gases or create a vacuum. |

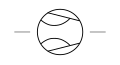

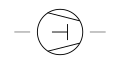

| Compressor Screw Type | A mechanical device that features intermeshing screws to compress gases. |

| Compressor Vacuum Pump Diaphragm Type | A mechanical device that employs a flexible diaphragm to compress gases or create a vacuum. |

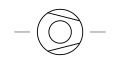

| Compressor Vacuum Pump | A general-purpose vacuum pump for diverse industrial applications. |

| Compressor Vacuum Pump Liquid Ring Type | A mechanical device that uses a liquid ring to compress gases and create a vacuum. |

| Compressor Vacuum Pump Reciprocating Piston Type | A mechanical device that uses a piston-cylinder mechanism to create a vacuum. |

| Compressor Vacuum Pump Roller Vane Type | A mechanical device that employs a rolling vane mechanism for gas compression and vacuum generation. |

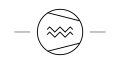

| Compressor Vacuum Pump Turbo Type | A mechanical device that uses high-speed rotating blades to generate a vacuum. |

Compressors are used in a variety of applications requiring gas compression or vacuum generation, including:

| Attribute | Details |

|---|---|

| Equipment Type | Compressor |

| Design | Centrifugal, Screw, Piston, Rotary, Liquid Ring |

| Operation | Gas Compression, Vacuum Creation |

| Standards | ISO 10628-2, ASME |

| Industries | Oil and Gas, Pharmaceuticals, Food and Beverage |

| Component | Material Options |

|---|---|

| Casing | Stainless Steel, Carbon Steel |

| Rotor/Impeller | Stainless Steel, Aluminum |

| Seals | PTFE, Graphite |

| Bearings | High-Speed, Ceramic |

| Attribute | Options |

|---|---|

| Capacity Range | 10 m³/h to 10,000 m³/h |

| Pressure Range | 0.1 bar to 500 bar |

| Speed Range | 500 to 50,000 RPM |

| Temperature Range | -40°C to 200°C |

| Accessory | Details |

|---|---|

| Control Panel | For automated operation |

| Vibration Monitoring System | Ensures operational safety |

| Cooling System | Air or water-cooled systems |

| Silencers | Reduces noise during operation |

| Attribute | Value |

|---|---|

| Material | Stainless Steel |

| Type | Screw Type |

| Capacity | 5,000 m³/h |

| Pressure Rating | 200 bar |

| Application | Gas Compression |

Explore micro data sheets for compressors using mD.

Explore vendors for compressors in your region using Mails AI.

| Parameter | Specification | Estimated Cost |

|---|---|---|

| Material | Carbon Steel | $10,000 - $100,000 |

| Type | Screw Type | $30,000 - $150,000 |

| Capacity | 5,000 m³/h | $50,000 - $200,000 |

For accurate pricing of compressors, access cost data using Cost AI.

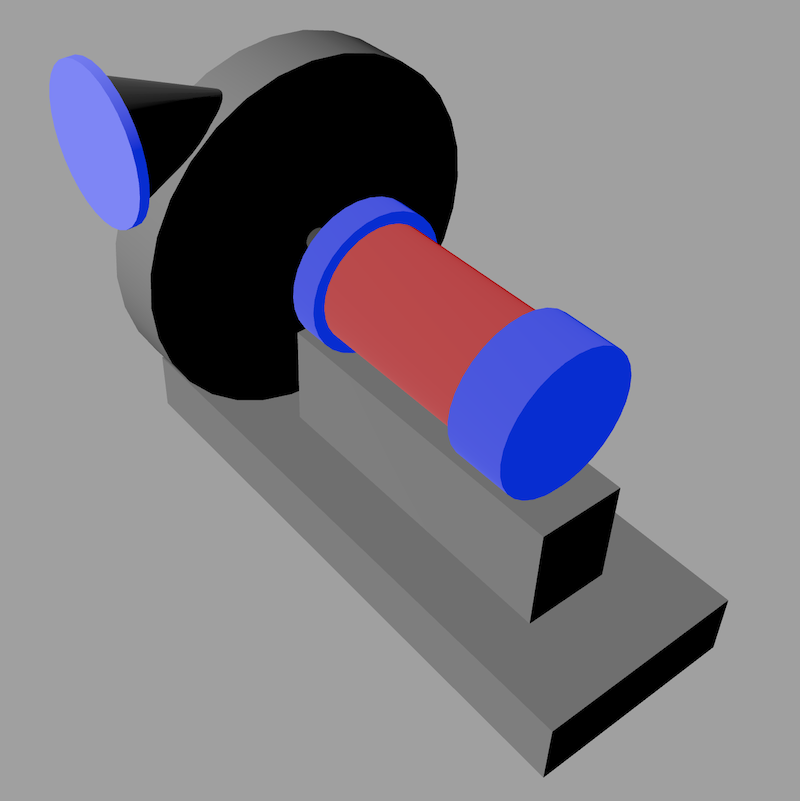

To integrate this 3D model of a compressor in a Process Plant use Model Builder. Download compressor.json. Choose File > Import and use the downloaded file to add the model to the scene. Choose Add > Light > Directional to add directional light.

Compressors are critical for enabling efficient gas compression and vacuum creation in industrial processes. Their diverse designs and operational capabilities make them suitable for a wide range of applications. Use this guide alongside tools like mD (Micro Data Sheets), Vendor Lists, and Cost AI to make informed decisions and optimize your processes.