Columns are essential equipment in industrial processes, designed to facilitate mass transfer, heat transfer, or chemical reactions. They are commonly used for distillation, absorption, stripping, and chemical reactions in industries such as petrochemicals, oil and gas, and pharmaceuticals. This guide covers various types of columns conforming to ISO 10628-2 standards.

Columns are represented in P&IDs with specific symbols indicating their internal configurations and process functions:

| Symbol | Name | Description |

|---|---|---|

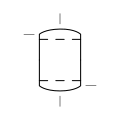

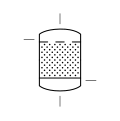

| Column | General-purpose column for mass and heat transfer processes. |

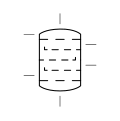

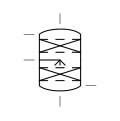

| Column with Staggered Baffle Trays | Column with baffle trays for improved liquid distribution and vapor flow. |

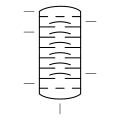

| Column with Bubble Cap Trays | Column equipped with bubble caps to enhance liquid-vapor interaction. |

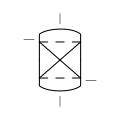

| Column with Fixed Bed | Column which contains a fixed bed of packing material for chemical reactions or absorption. |

| Column with Fluidized Bed | Column which features a fluidized bed for increased surface area and heat transfer. |

| Column with Two Fixed Bed Sections and Intermediate Spray Nozzle | Column which combines two fixed beds with an intermediate spray nozzle for improved distribution. |

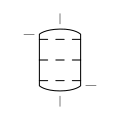

| Column with Valve Trays | Column which includes valve trays for dynamic control of liquid-vapor interaction. |

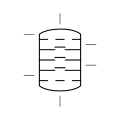

| Tray Column | Column which Comprises multiple trays to facilitate stepwise mass transfer. |

Columns are used in various applications requiring precise separation and reaction processes, including:

| Attribute | Details |

|---|---|

| Equipment Type | Column |

| Design | General, Staggered Baffle, Bubble Cap, Fixed Bed, Fluidized Bed |

| Operation | Continuous, Batch |

| Standards | ISO 10628-2, ASME |

| Industries | Petrochemicals, Pharmaceuticals, Chemicals |

| Component | Material Options |

|---|---|

| Shell | Stainless Steel, Carbon Steel |

| Trays | Stainless Steel, Alloy Steel |

| Packing | Ceramic, Plastic, Metal |

| Seals | PTFE, Graphite |

| Attribute | Options |

|---|---|

| Size Range | 1 meter to 10 meters in diameter |

| Height Range | 5 meters to 50 meters |

| Temperature Range | -20°C to 400°C |

| Pressure Rating | Up to 50 bar |

| Accessory | Details |

|---|---|

| Liquid Distributor | Ensures uniform liquid flow |

| Demister Pad | Reduces vapor entrainment |

| Temperature Sensors | Monitors internal process conditions |

| Sampling Ports | Allows for sampling during operation |

| Attribute | Value |

|---|---|

| Material | Stainless Steel |

| Type | Tray Column |

| Diameter | 3 meters |

| Height | 20 meters |

| Application | Distillation |

Explore micro data sheets for columns using mD.

Explore vendors for columns in your region using Mails AI.

| Parameter | Specification | Estimated Cost |

|---|---|---|

| Material | Carbon Steel | $50,000 - $500,000 |

| Type | Tray Column | $100,000 - $1,000,000 |

| Diameter | 3 meters | $200,000 - $800,000 |

For accurate pricing of columns, access cost data using Cost AI.

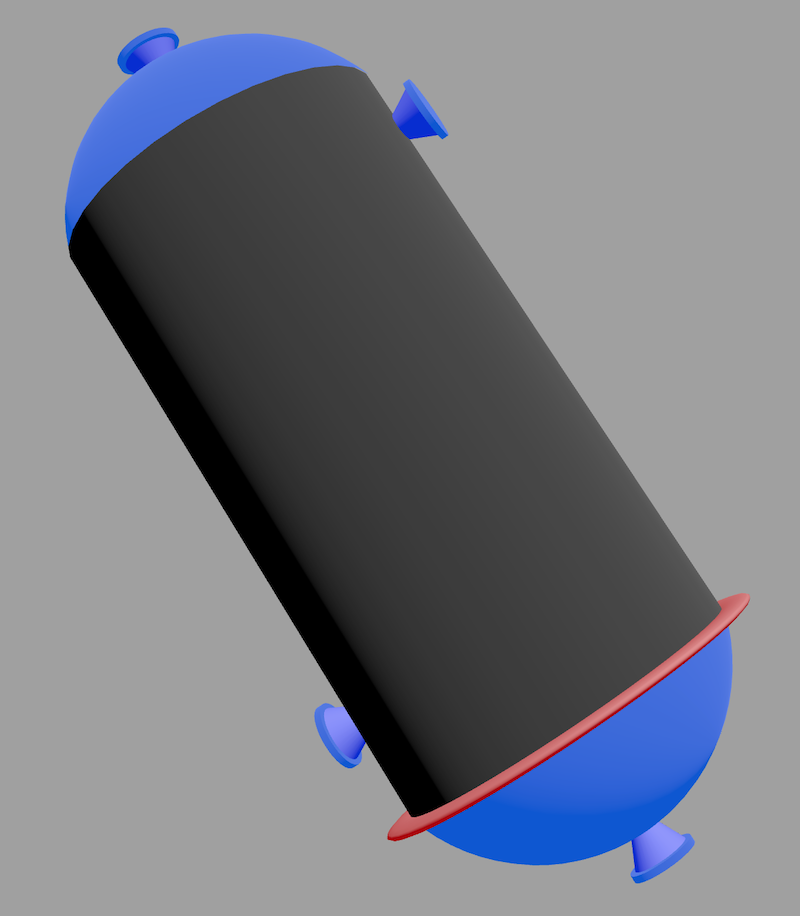

To integrate this 3D model of a column in a Process Plant use Model Builder. Download column.json. Choose File > Import and use the downloaded file to add the model to the scene. Choose Add > Light > Directional to add directional light.

Columns are integral to efficient mass transfer and chemical processes in various industries. Their diverse designs and operational capabilities make them adaptable for different applications. Use this guide alongside tools like mD (Micro Data Sheets), Vendor Lists, and Cost AI to make informed decisions and optimize your processes.