Centrifugal pumps are widely used mechanical devices designed to transport fluids by converting rotational energy from a motor into kinetic energy in the fluid. These pumps are essential in industries such as water treatment, oil and gas, chemical processing, and HVAC systems. Their simple design, efficiency, and ability to handle high flow rates make them a preferred choice for various applications.

Centrifugal pumps are represented in P&IDs with distinct symbols to convey their function and design:

| Symbol | Name | Description |

|---|---|---|

| Centrifugal Pump | A device for transporting fluids using centrifugal force. |

Centrifugal pumps are used in diverse applications requiring efficient fluid movement, including:

Single-Stage Centrifugal Pump

Multi-Stage Centrifugal Pump

Axial Flow Pump

Radial Flow Pump

Mixed Flow Pump

Sealless Pump

| Attribute | Details |

|---|---|

| Equipment Type | Centrifugal Pump |

| Design | Single-Stage, Multi-Stage, Axial Flow, Radial Flow |

| Operation | Continuous or Intermittent |

| Standards | ISO 5199, API 610 |

| Industries | Water Treatment, Oil and Gas, HVAC |

| Component | Material Options |

|---|---|

| Casing | Cast Iron, Stainless Steel |

| Impeller | Bronze, Stainless Steel |

| Shaft | Carbon Steel, Alloy Steel |

| Seals | Mechanical Seal, Packing |

| Attribute | Options |

|---|---|

| Capacity Range | 10 m³/h to 10,000 m³/h |

| Head Range | 5 m to 300 m |

| Operating Temperature | -20°C to 200°C |

| Pressure Rating | Up to 50 bar |

| Speed Range | 500 to 3,600 RPM |

| Accessory | Details |

|---|---|

| Strainers | Protects the pump from debris |

| Baseplate | Provides structural support |

| Couplings | Ensures proper alignment |

| Control Panel | Automates pump operation |

| Attribute | Value |

|---|---|

| Material | Cast Iron |

| Type | Single-Stage Radial Flow |

| Capacity | 500 m³/h |

| Head | 50 m |

| Application | Water Supply |

Explore micro data sheets for centrifugal pumps using mD.

Explore vendors for centrifugal pumps in your region using Mails AI.

| Parameter | Specification | Estimated Cost |

|---|---|---|

| Material | Cast Iron | $500 - $5,000 |

| Type | Multi-Stage | $3,000 - $20,000 |

| Capacity | 500 m³/h | $2,000 - $10,000 |

For accurate pricing of centrifugal pumps, access cost data using Cost AI.

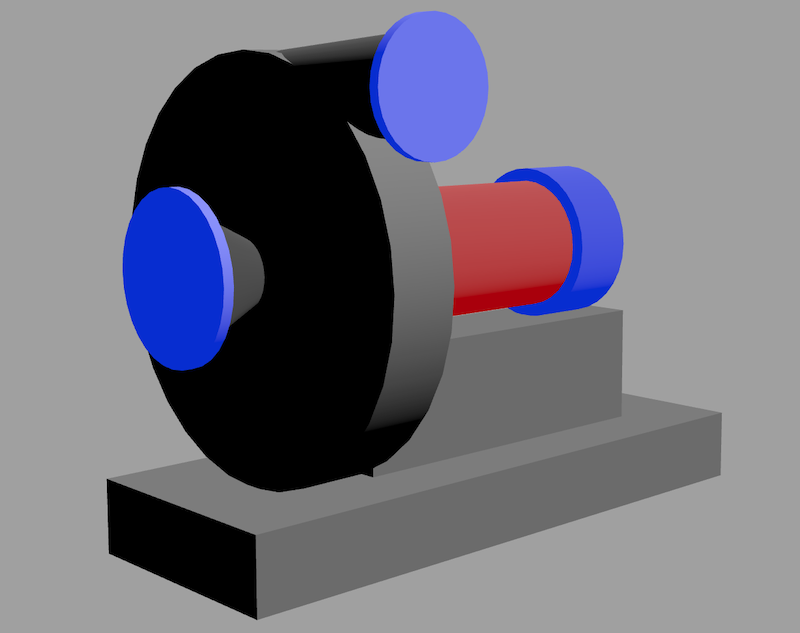

To integrate this 3D model of an centrifugal pump in a Process Plant use Model Builder. Download centrifugal-pump.json. Choose File > Import and use the downloaded file to add the model to the scene. Choose Add > Light > Directional to add directional light.

Centrifugal pumps are indispensable for fluid movement in industrial and commercial applications. Their robust design, efficiency, and versatility make them a preferred choice for various industries. Use this guide alongside tools like mD (Micro Data Sheets), Vendor Lists, and Cost AI to make informed decisions and optimize your processes.