Autoclaves are high-pressure vessels designed for sterilizing equipment, materials, and products using steam, heat, and pressure. These devices ensure effective sterilization in various industries such as pharmaceuticals, healthcare, food and beverage, and material processing. Autoclaves are known for their reliability, efficiency, and ability to handle a wide range of applications.

Autoclaves are represented in P&IDs with a distinct symbol highlighting their role as pressure vessels:

| Symbol | Name | Description |

|---|---|---|

| Autoclave | A high-pressure vessel used for sterilization and material processing. |

Autoclaves are used in a variety of applications requiring sterilization and high-pressure environments, including:

| Attribute | Details |

|---|---|

| Equipment Type | Autoclave |

| Design | Gravity, Vacuum, Horizontal, Jacketed |

| Operation | Steam, Heat, Pressure |

| Standards | ASME, ISO |

| Industries | Pharmaceuticals, Healthcare, Food and Beverage |

| Component | Material Options |

|---|---|

| Chamber | Stainless Steel, Carbon Steel |

| Jacket | Stainless Steel |

| Seals | PTFE, Silicone |

| Piping | Stainless Steel |

| Attribute | Options |

|---|---|

| Size Range | 50 to 10,000 liters |

| Temperature Range | 121°C to 134°C |

| Pressure Range | Up to 2.5 MPa |

| Cycle Time | 20 to 60 minutes |

| Power Supply | Electric, Steam |

| Accessory | Details |

|---|---|

| Data Logger | Tracks and records sterilization cycles |

| Steam Generator | For standalone operation |

| Load Carrier | Simplifies material handling |

| Vacuum Pump | Enhances air removal for efficient sterilization |

| Configuration | Details |

|---|---|

| Gravity Autoclave | 100-liter Chamber, Stainless Steel, Electric Heated |

| Horizontal Autoclave | 500-liter Chamber, Jacketed Design, Steam Heated |

| Vacuum Autoclave | 200-liter Chamber, Stainless Steel, Vacuum Pump Included |

| Parameter | Details |

|---|---|

| Warranty | 12-36 Months |

| Certifications | ISO 9001, CE, ASME |

| Testing | Factory Calibrated, Performance Verified |

| Attribute | Value |

|---|---|

| Material | Stainless Steel |

| Size | 200 liters |

| Temperature Range | 121°C to 134°C |

| Pressure Range | Up to 2.5 MPa |

| Type | Vacuum Autoclave |

Explore micro data sheets for autoclaves using mD.

Explore vendors for autoclaves in your region using Mails AI.

| Parameter | Specification | Estimated Cost |

|---|---|---|

| Material | Stainless Steel | $5,000 - $20,000 |

| Type | Vacuum Autoclave | $10,000 - $50,000 |

| Size (Volume) | 200 liters | $15,000 - $40,000 |

For accurate pricing of autoclaves, access cost data using Cost AI.

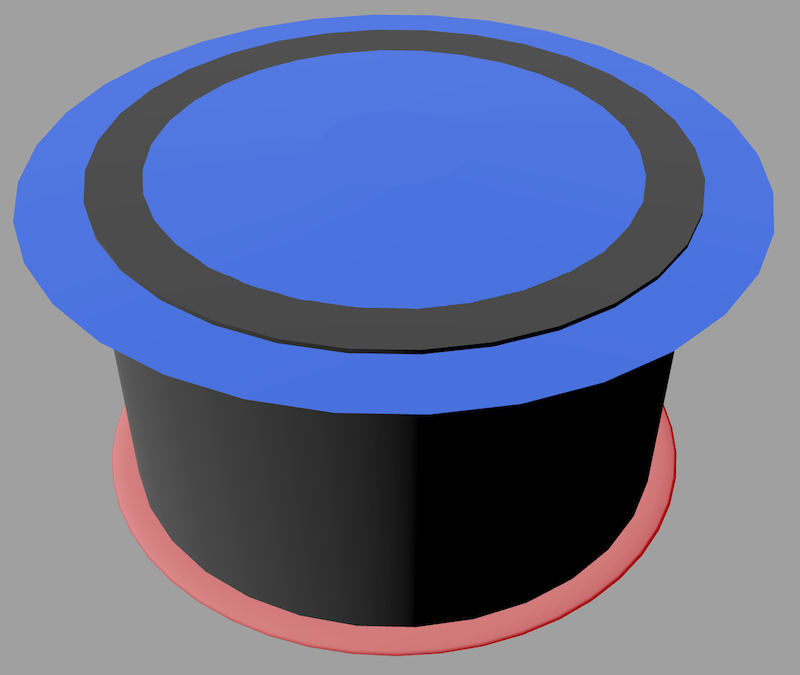

To integrate this 3D model of an autoclave in a Process Plant use Model Builder. Download autoclave.json. Choose File > Import and use the downloaded file to add the model to the scene. Choose Add > Light > Directional to add directional light.

Autoclaves are critical for sterilization and material processing across industries. Their robust design, versatility, and efficiency make them indispensable for engineers and operators. Use this guide alongside tools like mD (Micro Data Sheets), Vendor Lists, and Cost AI to make informed decisions and optimize your operations.