Globe valves are a popular choice for regulating and throttling flow in pipelines. Their unique design includes a spherical body and a movable disc, allowing precise flow control. These valves are extensively used in industries such as oil and gas, power generation, and chemical processing.

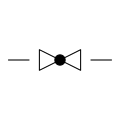

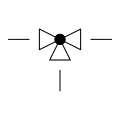

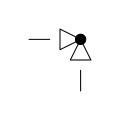

The globe valve is represented in P&IDs with a distinctive symbol:

| Symbol | Name | Description |

|---|---|---|

| Globe Valve | A valve with a disc that moves perpendicular to the seat for flow control. |

| 3-way Globe Valve | A valve with a disc that moves perpendicular to the seat to control a 3-way flow. |

| Angle Globe Valve | A valve with a disc that moves perpendicular to the seat to control an angular flow. |

Globe valves are used in a variety of applications, including:

| Attribute | Details |

|---|---|

| Valve Type | Globe Valve |

| Design | Tee, Angle, Wye Patterns |

| Operation | Manual, Pneumatic, Electric |

| Standards | ANSI, API, ISO, DIN |

| Industries | Oil & Gas, Power Generation, Water Treatment |

| Component | Material Options |

|---|---|

| Body | Cast Iron, Carbon Steel, Stainless Steel |

| Disc | Stainless Steel, Alloy Steel |

| Seat | PTFE, Metal |

| Stem | Stainless Steel |

| Attribute | Options |

|---|---|

| Size Range | 1/2 inch to 24 inches |

| Pressure Rating | ANSI Class 150, 300, 600 |

| Temperature Range | -20°F to 800°F (-29°C to 427°C) |

| End Connections | Flanged, Socket Weld, Butt Weld |

| Actuator Type | Details |

|---|---|

| Manual | Handwheel |

| Pneumatic | Double-Acting, Spring Return |

| Electric | On/Off, Modulating, Explosion-Proof |

| Attribute | Details |

|---|---|

| Leakage Class | Class IV (Metal Seat) |

| Flow Coefficient (Cv) | Varies by size and design |

| Cycle Life | 50,000+ Cycles (Depending on material and application) |

| Accessory | Details |

|---|---|

| Positioner | Analog or Digital |

| Limit Switches | Mechanical or Proximity |

| Solenoid Valve | For Pneumatic Actuators |

| Manual Override | Available for Pneumatic and Electric Actuators |

| Configuration | Details |

|---|---|

| Manual Operation | 6-inch Globe Valve, Carbon Steel Body, Flanged End, Handwheel |

| Pneumatic Actuation | 10-inch Globe Valve, Stainless Steel Disc, Spring Return Actuator, Socket Weld End |

| Electric Actuation | 12-inch Globe Valve, Alloy Steel Body, Explosion-Proof Actuator, Butt Weld End |

| Parameter | Details |

|---|---|

| Warranty | 12-24 Months |

| Certifications | ISO 9001, API 623, CE |

| Testing | Hydrostatic, Air Leakage |

| Attribute | Value |

|---|---|

| Material | Carbon Steel |

| Size | 8 inches |

| Pressure Rating | 300 PSI |

| Temperature Range | -20°F to 400°F |

| End Connection Type | Flanged |

| Actuator Type | Pneumatic |

Explore vendors for globe valves in your region using Mails AI.

| Parameter | Specification | Estimated Cost |

|---|---|---|

| Material | Cast Iron | $200 - $500 |

| Actuator Type | Electric | $800 - $2,000 |

| Size (Diameter) | 8 inches | $400 - $1,200 |

For accurate pricing of globe valves, access cost data using Cost AI.

To integrate a 3D model of a globe valve in a Process Plant use Model Builder.

Globe valves are indispensable for precise flow control in various industrial applications. Their robust design and versatile configurations make them a preferred choice for engineers. Use this guide alongside tools like mD (Micro Data Sheets), Vendor Lists, and Cost AI to make informed decisions and enhance your project outcomes.