Check valves are essential components in piping systems, designed to allow fluid flow in one direction and prevent backflow. Their simple yet effective mechanism ensures the protection of equipment and maintains system efficiency. Check valves are widely used in industries such as oil and gas, water treatment, and chemical processing.

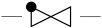

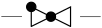

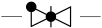

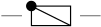

Check valves are represented in P&IDs with a clear symbol to indicate their unidirectional flow functionality:

| Symbol | Name | Description |

|---|---|---|

| Check Valve | A valve that allows flow in one direction and prevents backflow. |

| Check Valve | A globe type valve that allows flow in one direction and prevents backflow. |

| Check Valve | A swing type, form 1 valve that allows flow in one direction and prevents backflow. |

| Check Valve | A swing type, form 2 valve that allows flow in one direction and prevents backflow. |

Check valves are used in various applications to ensure unidirectional flow, including:

| Attribute | Details |

|---|---|

| Valve Type | Check Valve |

| Design | Swing, Lift, Ball |

| Operation | Self-Actuating |

| Standards | ANSI, API, ISO, DIN |

| Industries | Oil & Gas, Water Treatment, Power Generation |

| Component | Material Options |

|---|---|

| Body | Cast Iron, Carbon Steel, Stainless Steel |

| Disc | Stainless Steel, Alloy Steel |

| Seat | PTFE, Metal |

| Spring | Stainless Steel (for lift and ball types) |

| Attribute | Options |

|---|---|

| Size Range | 1/2 inch to 48 inches |

| Pressure Rating | ANSI Class 150, 300, 600 |

| Temperature Range | -20°F to 800°F (-29°C to 427°C) |

| End Connections | Flanged, Threaded, Butt Weld |

| Attribute | Details |

|---|---|

| Leakage Class | Class IV (Metal Seat) |

| Pressure Drop | Minimal in swing type |

| Cycle Life | 100,000+ Cycles |

| Accessory | Details |

|---|---|

| Position Indicator | Shows open or closed position (optional) |

| Backflow Preventer | Enhances system reliability |

| Configuration | Details |

|---|---|

| Swing Check Valve | 6-inch Valve, Carbon Steel Body, Flanged End |

| Lift Check Valve | 4-inch Valve, Stainless Steel Disc, Threaded End |

| Ball Check Valve | 2-inch Valve, Brass Body, PTFE Seat, Threaded End |

| Parameter | Details |

|---|---|

| Warranty | 12-24 Months |

| Certifications | ISO 9001, API 6D, CE |

| Testing | Hydrostatic, Air Leakage |

| Attribute | Value |

|---|---|

| Material | Stainless Steel |

| Size | 4 inches |

| Pressure Rating | 300 PSI |

| Temperature Range | -20°F to 400°F |

| End Connection Type | Flanged |

| Valve Type | Swing |

For accurate pricing of check valves, access cost data using Cost AI.

| Parameter | Specification | Estimated Cost |

|---|---|---|

| Material | Cast Iron | $150 - $500 |

| Valve Type | Swing | $200 - $1,000 |

| Size (Diameter) | 4 inches | $300 - $800 |

Explore vendors for check valves in your region using Mails AI.

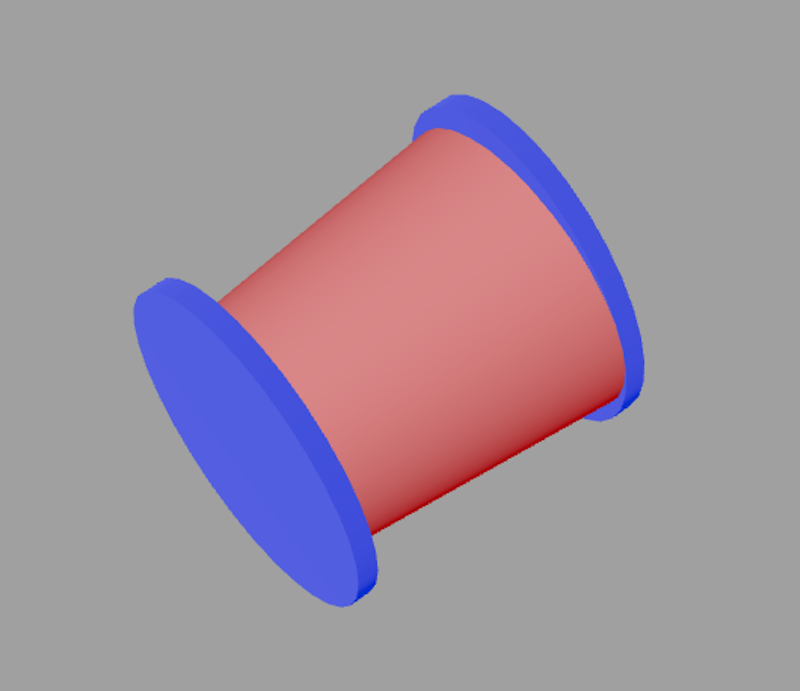

To integrate this 3D model of a check valve in a Process Plant use Model Builder. Download check-valve.json. Choose File > Import and use the downloaded file to add the model to the scene. Choose Add > Light > Directional to add directional light.

Check valves are crucial for maintaining unidirectional flow and protecting equipment in various industrial systems. Their reliability and diverse configurations make them indispensable for engineers. Use this guide alongside tools like mD (Micro Data Sheets), Vendor Lists, and Cost AI to make informed decisions and optimize your project outcomes.