Floating Production Storage and Offloading (FPSO) units play a pivotal role in offshore oil and gas production. While capital costs are a significant component of FPSO projects, operational costs often represent a substantial portion of the total lifecycle expenses. Understanding and accurately estimating these operational costs is essential for project feasibility and profitability. This blog post delves into the key components and considerations for operational cost estimation of FPSO units.

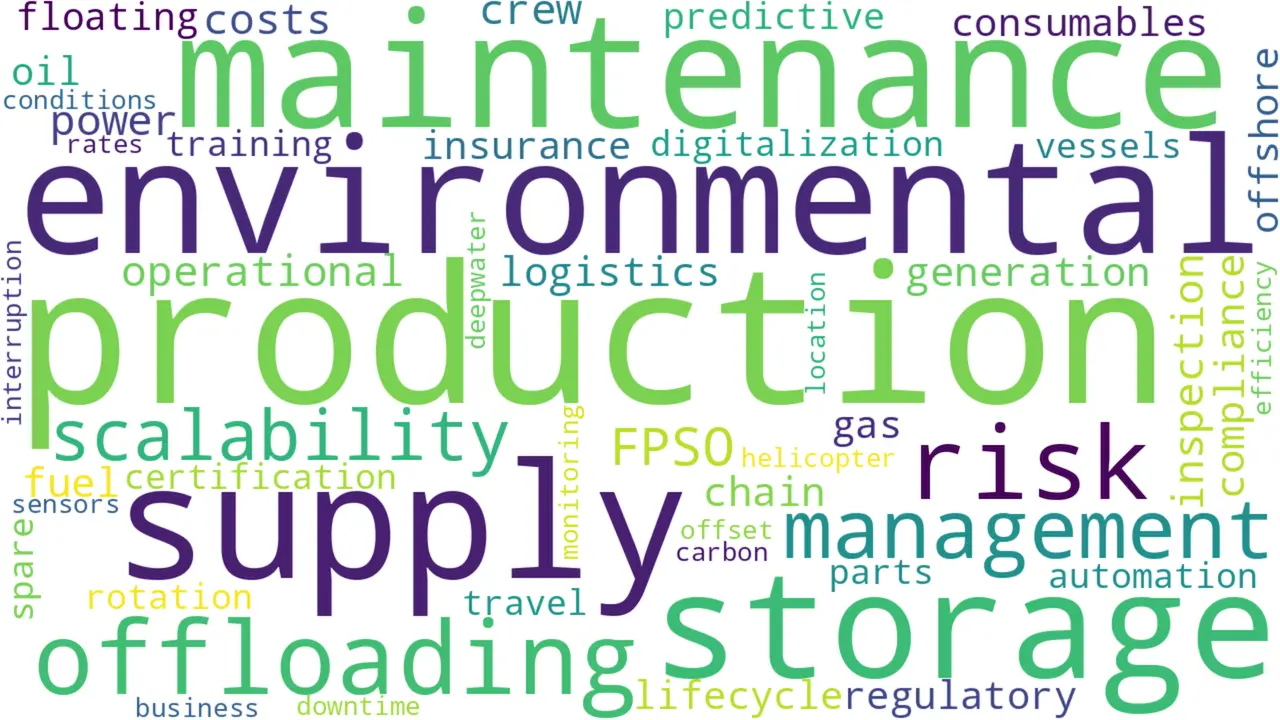

Operational costs for FPSOs can be broadly categorized into the following components:

Read More: Breakdown of Maintenance and Inspection Costs for FPSOs

Read More: Assess the Performance of a Cost Estimation

PlantFCE’s cost estimation tools can streamline the process by:

Accurate operational cost estimation is critical for the success of FPSO projects. By understanding the key cost drivers and leveraging modern tools and strategies, operators can optimize expenses and enhance profitability. Whether you’re managing an existing FPSO or planning a new project, a systematic approach to cost estimation can help navigate the complexities of offshore operations.

For more insights on cost estimation and optimization, explore PlantFCE’s comprehensive suite of tools tailored to the oil and gas industry.

Read More: PlantFCE: A fully integrated suite of tools for cost estimation