The global demand for Floating Production Storage and Offloading (FPSO) units has surged in recent years, driven by the growing need for offshore oil and gas exploration in deeper and more remote waters. One critical decision operators face when planning an FPSO project is whether to convert an existing tanker or build a new FPSO from scratch. This decision has far-reaching implications for project costs, timelines, and operational efficiency. In this blog post, we’ll compare the costs associated with FPSO conversion and new build projects, exploring key factors that influence this choice.

Converting an existing tanker into an FPSO is often perceived as a cost-effective solution. The primary cost components include:

The total conversion cost typically ranges from $150 million to $700 million, depending on the tanker’s condition and the complexity of the project.

A newly built FPSO offers a bespoke solution tailored to specific project requirements. The cost components include:

New build costs range from $1 billion to $3 billion, with higher expenditures associated with advanced features and larger capacities.

Read More: Capital Cost Estimation of a FPSO Vessel

FPSO conversion projects typically take 18 to 30 months to complete. The timeline can be expedited if the selected tanker is in good condition and the required modifications are minimal. However, unexpected issues, such as structural weaknesses, can lead to delays and increased costs.

Building an FPSO from scratch requires a longer timeline, usually between 36 and 48 months. The extended duration is due to the design, engineering, and construction phases. While new builds take longer, they offer the advantage of greater operational efficiency and reliability in the long term.

Read More: Guide to FPSO Charter Rate Estimation

Conversions are less flexible when it comes to accommodating changes in production capacity or adding new technology. The existing hull design imposes constraints on scalability.

New builds are designed with scalability in mind, allowing for upgrades and expansions to meet future production needs. This makes them a preferred choice for projects with high long-term potential.

Meeting modern environmental and regulatory standards can be challenging and costly for older vessels. Retrofitting additional equipment, such as gas flaring reduction systems, may be necessary.

New builds are designed to comply with the latest environmental and safety standards, including carbon capture and storage (CCS) technology and reduced emissions systems. This can result in lower operating costs and higher compliance in the long run.

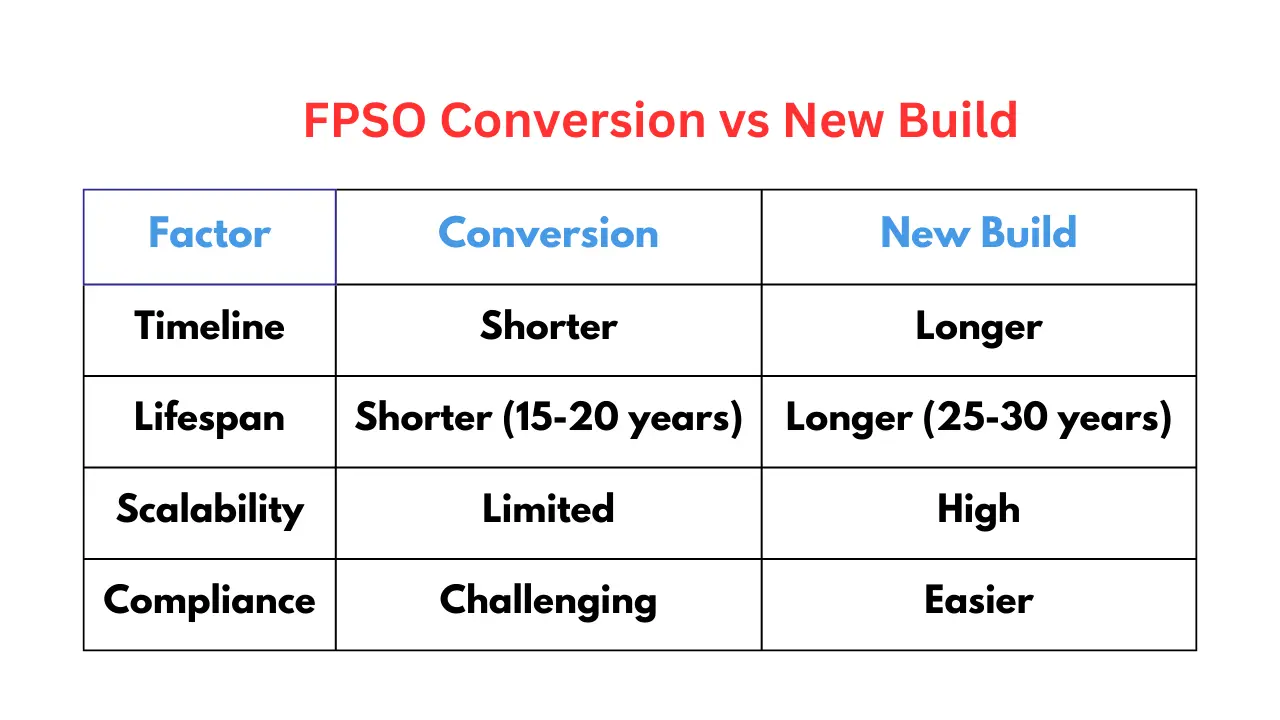

| Factor | Conversion | New Build |

|---|---|---|

| Initial Cost | Lower | Higher |

| Timeline | Shorter | Longer |

| Lifespan | Shorter (15-20 yrs) | Longer (25-30 yrs) |

| Scalability | Limited | High |

| Compliance | Challenging | Easier |

The choice between converting an existing tanker and building a new FPSO hinges on a balance of cost, timeline, and project requirements. While conversions offer a quicker and more affordable solution for shorter-term projects, new builds provide long-term reliability, scalability, and compliance with modern standards. Operators must carefully assess their project’s unique needs to make an informed decision that maximizes value and operational efficiency.

Whether you’re planning an FPSO conversion or considering a new build, accurate cost estimation and strategic planning are critical. Tools like PlantFCE can help streamline this process, providing data-driven insights to support your decision-making.

Read More: PlantFCE: A fully integrated suite of tools for cost estimation