Floating Production Storage and Offloading (FPSO) units have revolutionized offshore oil and gas production, offering unparalleled flexibility in deepwater and remote locations. However, like all offshore assets, FPSOs eventually reach the end of their operational life in a field. At this stage, operators face two primary options: decommissioning the FPSO or redeploying it to a new field. Both options entail significant costs and strategic considerations, which we explore in this blog post.

The Lifecycle of an FPSO

FPSOs are designed to operate in offshore fields for 15 to 30 years, depending on their build quality, maintenance, and field requirements. Once the field’s resources are depleted, or if operating conditions change, the FPSO must either be:

- Decommissioned: Permanently removed from service, dismantled, and disposed of.

- Redeployed: Refurbished and adapted for use in another field.

Decommissioning Costs of FPSOs

Decommissioning an FPSO is a complex and regulated process involving several key steps:

a. Disconnection and Demobilization

- Subsea Equipment Removal: Disconnecting risers, umbilicals, and flowlines.

- Mooring System Removal: Dismantling anchors and mooring lines.

- Transportation to Shore: Towing the FPSO to a dismantling yard.

b. Dismantling and Recycling

- Hull and Topside Dismantling: Breaking down the FPSO structure.

- Recycling of Materials: Salvaging steel, machinery, and other materials for resale or reuse.

- Waste Disposal: Managing hazardous waste in compliance with environmental regulations.

c. Environmental and Regulatory Compliance

- Permit Acquisition: Securing permits for decommissioning activities.

- Environmental Impact Mitigation: Ensuring minimal disruption to marine ecosystems.

- Monitoring: Conducting post-decommissioning environmental assessments.

Estimated Costs

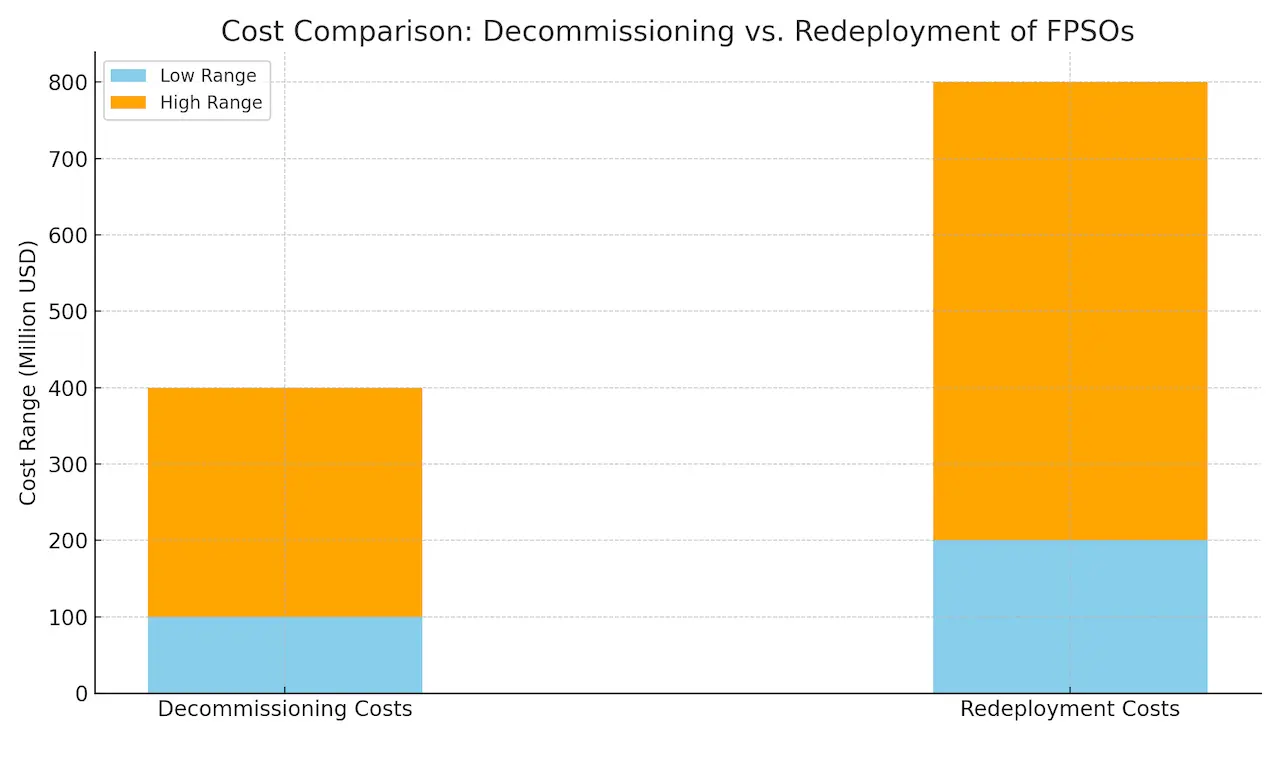

Decommissioning costs for an FPSO typically range from $100 million to $300 million, depending on factors such as location, water depth, and regulatory requirements.

Redeployment Costs of FPSOs

Redeploying an FPSO involves refurbishing and upgrading the unit for operation in a new field. Key cost components include:

a. Inspection and Assessment

- Evaluating the FPSO’s structural integrity, hull condition, and topside equipment.

- Conducting detailed surveys to identify necessary repairs and upgrades.

b. Refurbishment and Upgrades

- Structural Modifications: Reinforcing the hull and modifying topside facilities to meet new field requirements.

- Technological Upgrades: Installing advanced equipment, automation systems, and emissions control technologies.

- Regulatory Compliance: Ensuring the FPSO meets the environmental and safety standards of the new region.

c. Mobilization to the New Field

- Towing and Mooring: Transporting the FPSO and establishing mooring systems at the new location.

- Integration with Subsea Infrastructure: Connecting the FPSO to risers, umbilicals, and other subsea components.

Estimated Costs

Redeployment costs generally range from $200 million to $600 million, depending on the FPSO’s condition and the complexity of the new field’s requirements.

Read More: FPSO Conversion vs. New Build: A Cost Comparison

Factors Influencing Costs

a. Location and Water Depth

- Harsh environments and deepwater fields increase the costs of both decommissioning and redeployment due to logistical challenges.

b. Age and Condition of the FPSO

- Older units require more extensive refurbishment or may not be suitable for redeployment, leading to higher costs.

c. Regulatory Requirements

- Stringent environmental and safety regulations can add significant costs, particularly for decommissioning.

d. Market Demand

- High demand for FPSOs can make redeployment a more attractive option, potentially offsetting refurbishment costs.

Strategic Considerations

a. Decommissioning

- Ideal for units at the end of their structural or economic life.

- Reduces long-term liability but incurs high upfront costs.

- Supports environmental sustainability through recycling.

b. Redeployment

- Suitable for FPSOs with strong structural integrity and scalability.

- Provides cost savings compared to building a new unit.

- Requires a thorough understanding of the new field’s operational needs.

Accurate cost estimation and strategic planning are crucial for decommissioning and redeployment decisions. Tools like PlantFCE’s cost estimation suite can provide:

- Detailed breakdowns of decommissioning and refurbishment costs.

- Advanced analytics to compare cost scenarios.

- Regulatory compliance checklists to streamline project execution.

Read More: PlantFCE: A fully integrated suite of tools for cost estimation

Conclusion

Decommissioning and redeployment are pivotal stages in the lifecycle of an FPSO, each with its own set of challenges and costs. While decommissioning ensures safe and sustainable disposal, redeployment offers an opportunity to extend the asset’s life and maximize return on investment. By carefully assessing costs, regulatory requirements, and operational goals, operators can make informed decisions that align with their strategic priorities.

For more insights and tools to support FPSO cost estimation, explore PlantFCE’s comprehensive solutions tailored to the offshore oil and gas industry.