In complex industrial facilities like chemical plants, refineries, and power plants, routing pipes is much more than simply connecting point A to point B. The ideal pipe route must be economical, maintainable, safe, and constructible. Yet, traditional routing techniques often struggle under real-world constraints — space limitations, design standards, and cross-discipline clashes.

This blog introduces a layered, rule-driven approach to pipe routing — one that mirrors how a vehicle navigates a city, while honoring engineering principles and spatial discipline.

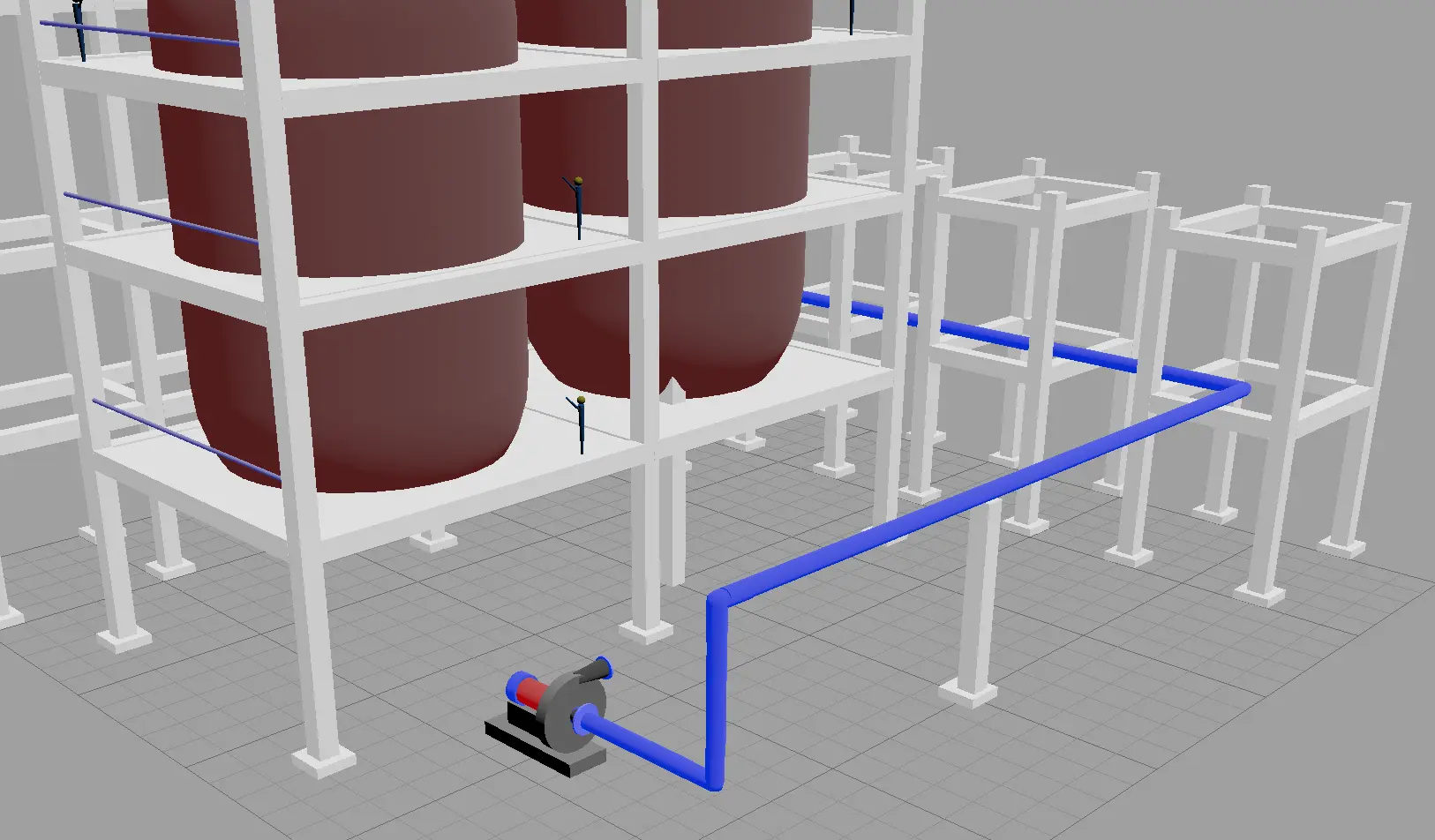

Imagine a pipe as a car trying to move between two parking spots:

This analogy guides how we structure our routing approach.

We break down routing into three distinct layers:

Before any automated routing begins, we plan the “first and last mile” — the connections at both ends.

Every pump, heat exchanger, or compressor has a predictable inlet/outlet geometry. So why redraw every time?

Just like buildings have standard fire exits, your pipe rack should have:

These two actions drastically reduce layout complexity at the interface points.

Think of these like flyover decks:

To avoid future conflicts:

Example: On a floor ABCD with the rack on side A–B, assign:

This gives automated routing algorithms “safe zones” to operate within.

With rules, levels, and connection points in place, the final leg is computational:

By only applying algorithms after engineering intelligence has been embedded, we avoid the classic pitfalls of blind automation.

| Challenge | Solved By |

|---|---|

| Random elbows and loops | Predefined stubs + elbow penalties |

| Cross-discipline clashes | Pipe corridors + level segregation |

| Maintenance nightmares | Entry/exit standardization |

| Routing failure in tight spaces | Early constraint injection |

| Software overreach | Rules before algorithms |

This method reduces rework, clarifies responsibilities, and creates audit-friendly, traceable layouts.

By combining engineering expertise with computational methods, you can build a smarter, faster, and safer piping system.

This isn’t just routing. This is intelligent infrastructure design.